Use of 5G for future projects.

The excavator was controlled remotely via 5G transmission, ensuring that no people were in the danger zone. Four large screens support precise control of the excavator.

This is precisely the direction ETH Zurich is heading in. The Robotics Systems Lab researches the development of machines and their intelligence when it comes to operating in harsh and demanding environments. A winner of the Swisscom StartUp Challenge 2020, the prototype of an autonomous excavator was presented a few weeks ago.

cablex was also involved in the preparations at ETH Zurich to follow the excavator training based on 5G technology. The main role in the pilot test was taken by a teleoperated excavator that can carry out excavation work in risky quarry regions without endangering people and the environment.

The installations.

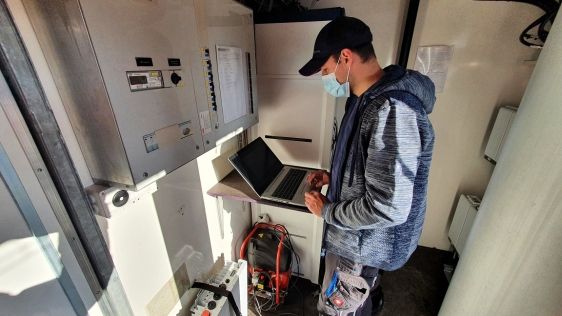

To carry out the pilot test, the test site at the ETH Hönggerberg campus was connected to electricity and optical fibres. The 5G antenna was installed on a specially erected container. cablex technicians carried out the complete integration in the container. The tele-base station, which hosted the platform from which the excavator was controlled, was built in a second container.

The used excavator was also equipped with a 5G antenna, as well as audio and networking equipment, laser scanners, computers and various cameras.

The results.

The excavator successfully carried out the excavation work in the pilot test. It was controlled by human hand with the help of four screens. The control platform was located outside the danger zone.

Thanks to its low latency, 5G technology ensured fast and easy excavator operation in the robotics project.

The high bandwidth transmitted high-resolution images in the shortest possible time, enabling accurate and pinpoint control.

We are looking forward to more projects in the future that we can implement together with Swisscom. 5G technology promises exciting developments in the field of automation, and we can now definitively say that we have long since left the realm of science fiction.