Demolition of a railway bridge in Montreux.

Inside an SBB bridge, copper and optical fibre cables of Swisscom. To enable the demolition work, cablex had to reroute the cables.

In order to reroute the Swisscom cables, the cablex project team of the CBU business unit, together with the SBB and a civil engineering company, decided to build a temporary structure about 20 metres from bridge to be demolished. A framework is used to support the cable pipes laterally and to guide them over the train tracks using a metal crossbar. As soon as the new SBB bridge is completed, the cables will be laid back in their original place inside the bridge.

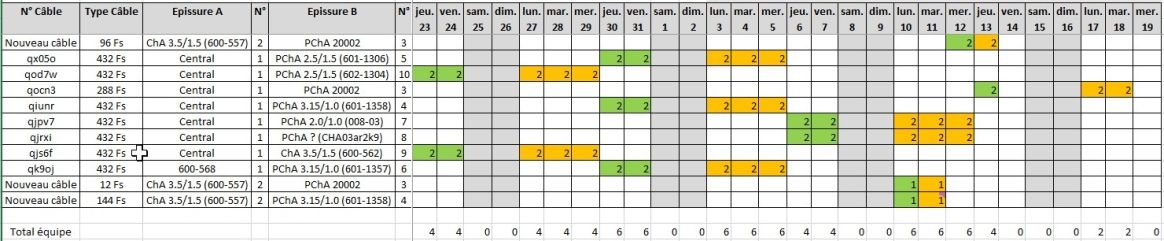

The demolition of the bridge required the re-routing of the following cables:

2 copper cables - 1800

2 optical fibre cables for Fibre to the Office (FTTO) with 10 and 120 fibres

11 cables for Fibre to the Home (FTTH) connections:

- 7 x 432 fibres

- 1 x 288 fibres

- 1 x 48 fibres

- 2 x 24 fibres

The tight time frame left no room for error.

The demolition of the bridge was scheduled for the night from August 29 to 30. This meant the cablex project team only had two months for planning and realising the re-routing of the cables after receiving the Swisscom mandate. Since the work of cablex involved temporary network interruptions, the affected customers had to be notified 20 days in advance - a circumstance that put additional strain on the already tight schedule.

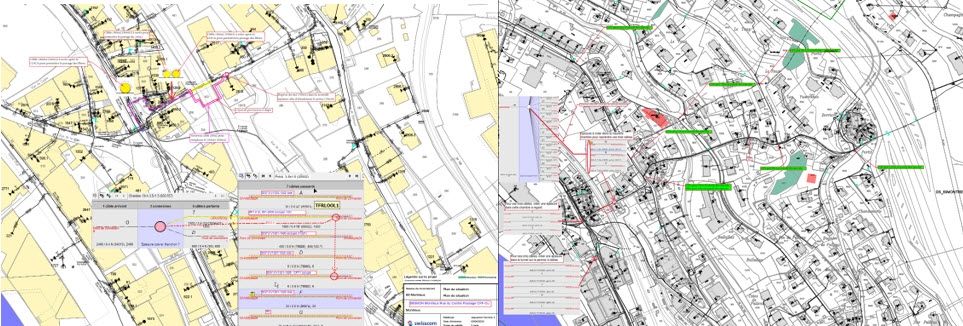

All of the involved parties knew: there was no room for mistakes! A detailed project analysis and on-site feasibility study had top priority: the splice points were determined based on the project analysis. As part of the on-site feasibility study, all of the manholes were opened, the cables running through them identified, sleeves exposed and the available cable reserves checked. It was important to gain an overview of how much space the manholes still offered for the installation of new sleeves. At the same time, the effects of the cable re-routing on road traffic and bus lines were evaluated in order to minimize the disturbances as much as possible.

During the course of the on-site analysis, the cablex project team also decided to disconnect and remove the two 1800-wire copper cables and replace them with a 200 x 2 copper cables. Removing the large 1800 copper cables, which were only partially used, created space in the cable ducts to pull through the new FTTH and FTTO cables as part of the re-routing activities.

This detailed situation analysis formed the basis for the creation of a detailed work plan, as well as for the organization of the schedule for switching (UMSA). Special care must be taken when planning an UMSA, as customers must be notified 20 days in advance of the network interruption associated with the switching.

To set up the temporary arrangement, the cables were cut in the area before and after the bridge. This meant two new sleeves were needed per cable. The cables in the section after the bridge were separated at the point where the (cable) reserves were located. The new sleeves were placed in the same location as before in the manhole. In the cable route in front of the bridge, i.e. between the local exchange and bridge, a different approach was chosen together with Swisscom: To reduce the space needed in the connecting shafts, the new sleeves were to be installed directly in the distribution chamber of the exchange.

The time frame was very tight.

Four to six teams were in action at any one time, in order to ensure the deadlines could be met!

Overall, 200 days per employee were planned for assembly work and 60 days per employee for pulling through the cables.

For each of the seven 432-fibre cables, two preparation days were planned, which were followed by three days for switching. The separation of the cable before and after the bridge was completed synchronously, that means the cables were separated and then spliced again directly afterwards. As a result of this, the impact on customers of cable re-routing and UMSA activities could be kept to a minimum. The duration of the interruption at the customers' locations was one hour at most.

Cable installation for the temporary arrangement:

- 5600 metres of optical fibre cables with 432 fibres

- 560 metr's of optical fibre cables with 288 fibres

In November, the fiber optic and copper cables will be laid in split pipes inside the new bridge. The cable reserves will then be stored in the shafts in front of and behind the bridge.

Interview partner Sébastien Charles Mallaun, Teamleader West Build Wireline at cablex says:

"In my opinion, this project illustrates the qualities of cablex very well: the ability to mobilise quickly and efficiently, in order to achieve great things! I would like to express my praise and thanks for the cooperation between the departments and regions, for the mutual support and flexibility, especially during vacation periods and with the additional restrictions imposed by corona".