Overhead line installers.

Our network heroes in overhead line construction have to adapt flexibly to local conditions such as high groundwater levels or rocky subsoil.

On behalf of Swisscom, the campsite in Giswil was connected with optical fibre via overhead lines. The project was an opportunity to show how flexible the design of an optical fibre expansion can be and how adaptable cablex has to approach network construction in order to best meet local conditions. In Giswil, the overhead line team had to deal with flowing bodies of water, heavy truck traffic around the plant, a high groundwater table and soft subsoil. It was impressive to watch, but also everyday business for our experienced network construction professionals, who didn't let themselves get rattled for a second.

In the ground, over water and in the air.

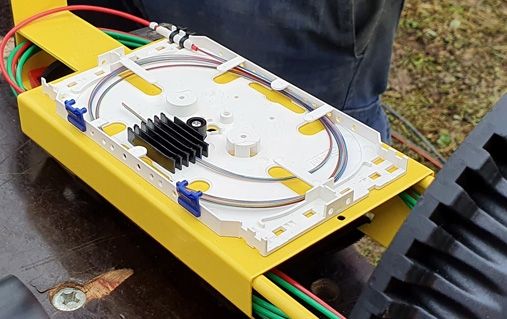

The campsite’s upgrade via overhead line began in a shaft on the dam of the Sarner Aa. This shaft was rebuilt for the campsite’s optical fibre expansion. It is here, and not as perhaps expected on the mast, that the new optical fibre cable and the main cable from the exchange in Giswil are spliced in what’s called an UCN closure (splice closure). This variant has the advantage that no new spliceable (UST-KVS) mast has to be installed.

However, the construction of the new shaft on the dam also required additional commitment: In this case, it was necessary to ensure that no damage was caused to the dam by the excavation of the shaft trench and above all the weight of the excavator. Appropriate special permits were obtained for this purpose. Starting from the newly constructed shaft, the cable initially runs a few metres underground to the mast on the Sarner Aa dam.

From here, the aerial cable runs up the mast and is led across the river to the opposite bank. Once the aerial cable reaches the gravel plant site, it is routed back towards the ground. Due to the heavy traffic comprised of large gravel trucks, the optical fibre cable has to pulled underground in the area of the plant site. This measure is intended to prevent one of the powerful trucks from getting caught on the overhead line and damaging the optical fibre cable when driving in and out of the gravel plant.

Interesting...

Aerial cables may run underground for a maximum distance of five metres. In orderto cover a distance of 100 metres of factory premises a suitable optical fibre cable was installed in existing underground cable ducts. The "underground" cable was spliced with the aerial cable in the masts’ KVS box (grey splice box) on this side and on the other side of the factory premises.

Pendant ce temps-là …

Parallèlement, deux monteurs de lignes aériennes se chargeaient de poser le câble dans le terrain marécageux entre le camping et la gravière sur sept poteaux de 8 mètres de hauteur. Comme le niveau de la nappe phréatique est élevé, le sol dans lequel se trouvent les poteaux est très détrempé. Il faut donc sécuriser soigneusement les pylônes.

Outlook.

On the day of the site visit, the overhead line team announced further exciting projects. So we'll soon be heading up high into the mountains of the Alpnach region.